In the world of modern architecture, sustainable and innovative building materials have become a primary focus for architects and designers.

One such material that has gained significant popularity is Fluted Wood-Plastic Composite (WPC) Panels.

Architects are increasingly turning to these panels for various projects due to their exceptional properties and versatility.

In this article, we will delve into the reasons why architects love fluted WPC panels, offering an insider’s perspective on their benefits and advantages.

Eco-Friendly Manufacturing: A Responsible Choice

One of the primary reasons architects are drawn to fluted WPC panels is their eco-friendly manufacturing process.

WPC panels are crafted using a combination of wood fibers or sawdust and recycled plastic materials.

The wood fibers are sourced from sustainable forestry practices, ensuring responsible harvesting and reducing the environmental impact.

The use of recycled plastic not only diverts waste from landfills but also lessens the dependency on virgin plastics.

As architects become increasingly concerned about sustainable building practices, fluted WPC panels provide a responsible choice that aligns with their green building objectives.

Architects are keen on collaborating with manufacturers and suppliers who adhere to environmentally-conscious production methods.

They seek WPC panels that are certified and meet industry standards, ensuring that the products used in their projects contribute to a greener and more sustainable future.

Versatility in Design: Unleashing Creativity

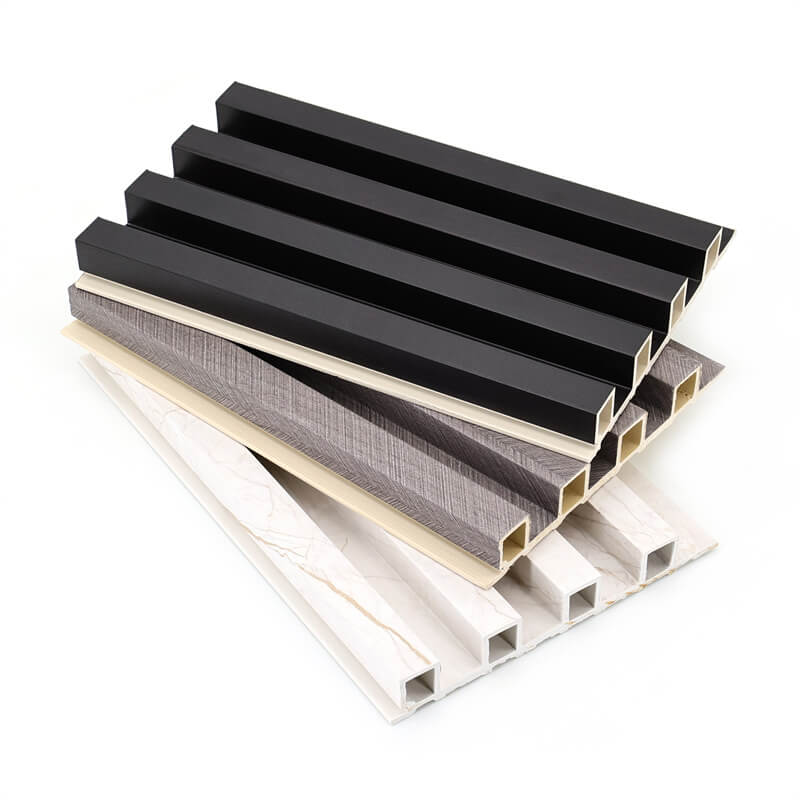

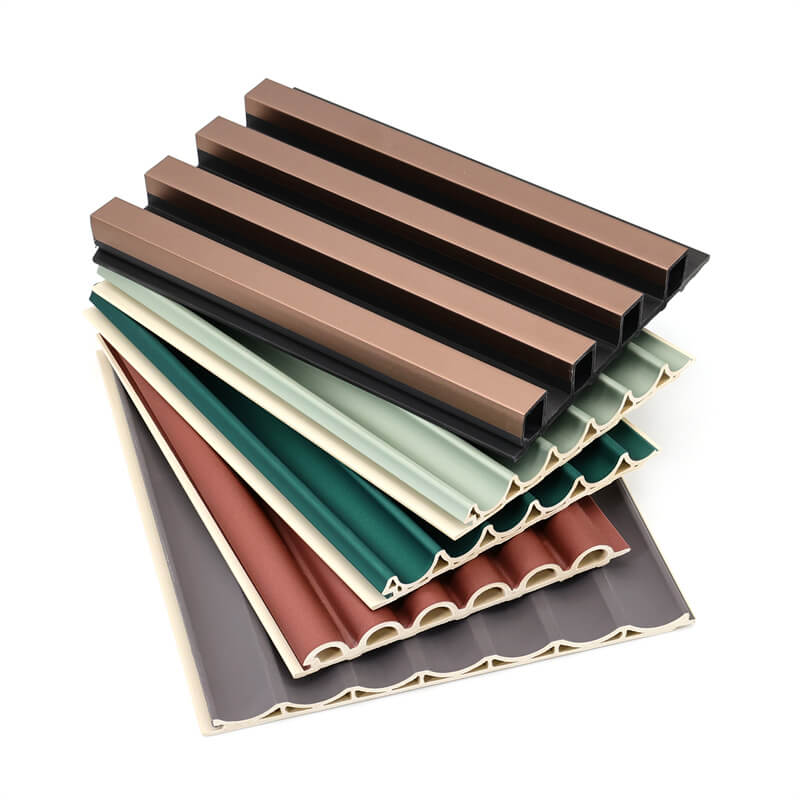

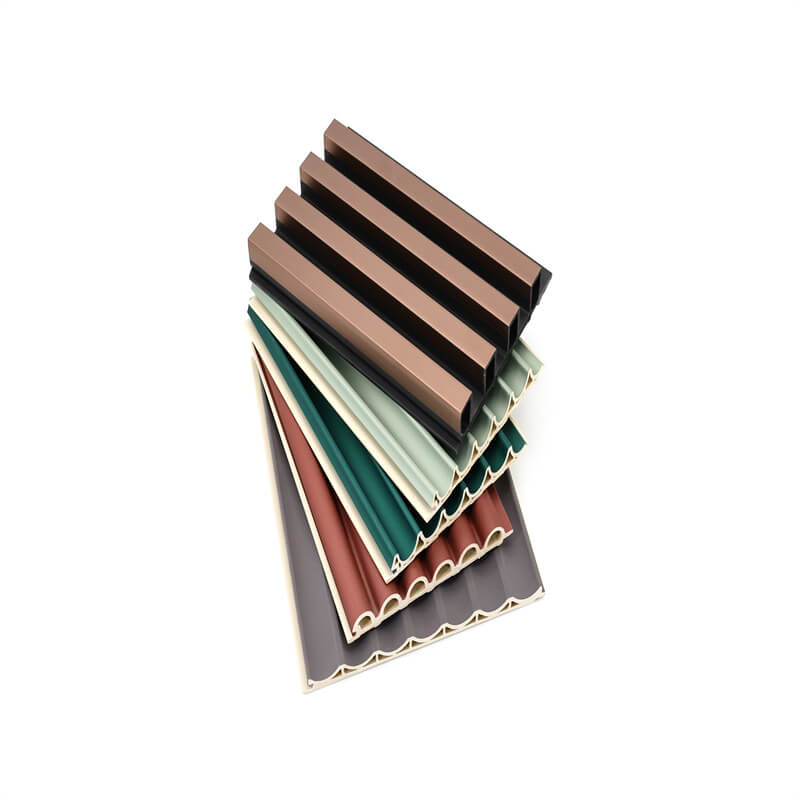

Fluted WPC panels offer architects an incredible range of design possibilities.

These panels can be manufactured in various shapes, sizes, and colors, allowing architects to unleash their creativity and bring their unique design visions to life.

Whether used for exterior cladding, interior wall paneling, ceilings, or decorative elements, fluted WPC panels add a touch of modern elegance to any architectural project.

They can emulate the appearance of natural wood while providing the benefits of a synthetic material – durability, resistance to moisture, and minimal maintenance requirements.

Moreover, architects appreciate the ease with which they can customize fluted WPC panels.

These panels can be easily cut, shaped, and joined, enabling architects to create intricate designs and unique patterns.

This level of flexibility is a significant advantage, especially for projects that demand innovative and eye-catching aesthetics.

Cost-Effective and Time-Efficient Solutions

Beyond the aesthetic appeal and eco-friendliness, fluted WPC panels offer architects a cost-effective and time-efficient solution for their projects.

Traditional materials like natural wood can be expensive, and their procurement might contribute to deforestation.

On the other hand, fluted WPC panels present an affordable alternative without compromising on quality or appearance.

Additionally, the installation process for fluted WPC panels is relatively straightforward, thanks to their lightweight nature and interlocking system.

Architects can save both time and labor costs during the installation phase, making these panels an attractive choice for commercial projects with tight deadlines.

The low maintenance requirements of fluted WPC panels further contribute to cost-effectiveness over the long term.

Unlike natural wood, these panels do not require regular staining, painting, or sealing.

Architects can confidently specify these panels, knowing that their clients will benefit from reduced maintenance expenses.

Factory-Made Precision and Consistency

Another aspect that appeals to architects is the precision and consistency achieved through factory manufacturing of fluted WPC panels.

Unlike on-site construction, factory production ensures that each panel meets the exact specifications and quality standards set by the manufacturer.

Factory-made panels are not susceptible to variations caused by weather conditions or the skill level of individual workers.

This level of consistency translates into predictable results for architects, ensuring that their design concepts are executed precisely as envisioned.

Furthermore, manufacturers can provide architects with a wide range of samples to help them make informed decisions during the design phase.

The availability of samples allows architects to assess the texture, color, and finish of the fluted WPC panels, ensuring that the final product aligns perfectly with the overall design scheme.

Fluted WPC panels have won the hearts of architects with their eco-friendly manufacturing, design versatility, cost-effectiveness, and factory-made precision.

As the architectural world continues to prioritize sustainability and innovative solutions, the popularity of fluted WPC panels is bound to soar.

Architects will continue to appreciate these panels as they transform architectural visions into stunning and environmentally-responsible realities.