As the construction industry increasingly embraces sustainable practices, the demand for environmentally friendly building materials has surged.

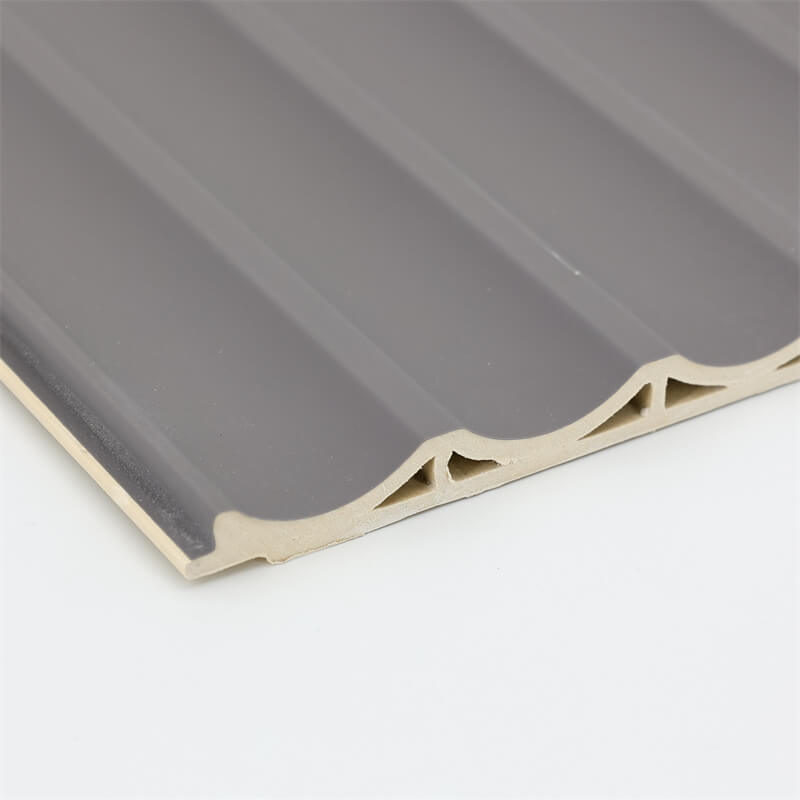

Fluted Wood-Plastic Composite (WPC) Panels have emerged as a popular choice for architects and builders seeking greener alternatives in construction.

These panels combine the natural appeal of wood with the durability of recycled plastic, offering a range of environmental advantages that make them an ideal choice for sustainable building projects.

In this article, we will explore the environmental benefits of fluted WPC panels and how they contribute to a more eco-friendly construction industry.

Sustainable Sourcing of Materials

One of the significant environmental advantages of fluted WPC panels lies in the sustainable sourcing of raw materials.

The wood fibers or sawdust used in WPC panels are typically obtained from responsibly managed forests.

This ensures that the harvesting of trees is done in a manner that maintains the ecological balance and biodiversity of the forest.

Moreover, the plastic component of WPC panels is derived from recycled materials, often sourced from post-consumer waste like plastic bottles and packaging materials.

By using recycled plastic, the demand for virgin plastics is reduced, which in turn helps to alleviate the environmental burden associated with plastic production.

Architects and builders who prioritize sustainable construction can confidently choose fluted WPC panels, knowing that the materials used in their projects are obtained through eco-friendly sourcing practices.

Reduced Carbon Footprint

Fluted WPC panels contribute to a reduced carbon footprint compared to traditional building materials.

The manufacturing process of these panels consumes less energy and emits fewer greenhouse gases compared to the production of cement, steel, or other high-energy materials.

Furthermore, the use of recycled plastic in WPC panels diverts plastic waste from landfills, reducing the release of harmful greenhouse gases that result from the decomposition of plastic.

By opting for fluted WPC panels, the construction industry plays a significant role in curbing carbon emissions and combating climate change.

Minimal Waste and Recyclability

Fluted WPC panels are engineered to minimize waste during production.

Manufacturers can carefully control the production process to ensure that there is minimal material waste.

Any excess material generated during production can often be recycled and incorporated back into the manufacturing process, reducing the overall environmental impact.

Additionally, at the end of their lifecycle, fluted WPC panels can be recycled into new products or repurposed for other applications.

This recyclability reduces the burden on landfills and conserves resources, making WPC panels a sustainable and circular material choice.

Longevity and Low Maintenance

The durability of fluted WPC panels contributes to their environmental advantage.

These panels are highly resistant to rot, decay, and pests, which ensures a longer lifespan for buildings and structures where they are used.

Unlike natural wood, fluted WPC panels do not require frequent maintenance, such as staining, painting, or sealing.

This translates to reduced consumption of additional materials like paint and chemicals, further minimizing the environmental impact.

Additionally, the longevity and low maintenance requirements of fluted WPC panels reduce the need for frequent replacements, which in turn decreases the consumption of new materials and lowers construction waste.

Fluted WPC panels present a host of environmental advantages that make them a sustainable choice in construction.

From sourcing materials responsibly to reducing the carbon footprint, the use of recycled plastic, minimal waste, and recyclability, these panels contribute positively to the environment throughout their lifecycle.

Moreover, their durability and low maintenance requirements ensure that the materials used in construction last longer, reducing the need for frequent replacements and further minimizing environmental impact.

As the construction industry continues to prioritize sustainability and eco-conscious building practices, fluted WPC panels will remain at the forefront of innovative and environmentally friendly building materials.

Architects, builders, and manufacturers alike can collaborate to create greener and more sustainable spaces that not only meet the needs of the present but also contribute to a healthier and more sustainable future for generations to come.